- 氣力輸送系統(tǒng)的構(gòu)成和應(yīng)用分類

- 氣力輸送系統(tǒng)的運(yùn)營流程和性能特點(diǎn)分析

- 旋轉(zhuǎn)供料器氣路系統(tǒng)解析

- 倉泵輸送物料的保溫需求:哪些物料需保溫及原因

- 三葉羅茨鼓風(fēng)機(jī)的顯著優(yōu)勢

- 倉泵的奧秘:從結(jié)構(gòu)形式到物料輸送之道

- 氣力輸送系統(tǒng):系統(tǒng)構(gòu)成相關(guān)解析

- 旋轉(zhuǎn)供料器工作原理及主要功能是什么?聯(lián)系我們

濟(jì)南鑫魯泉盛機(jī)械設(shè)備有限公司

濟(jì)南鑫魯泉盛機(jī)械設(shè)備有限公司

服務(wù)熱線:15662735099

聯(lián)系地址:山東章丘棗園經(jīng)濟(jì)開發(fā)區(qū)

旋轉(zhuǎn)供料器氣路系統(tǒng)解析

旋轉(zhuǎn)供料器的氣路系統(tǒng)是保障其與氣力輸送系統(tǒng)協(xié)同運(yùn)行的核心,通過合理的氣壓控制與氣流分配

The pneumatic system of the rotary feeder is the core to ensure its coordinated operation with the pneumatic conveying system. Through reasonable air pressure control and airflow distribution, material sealing conveying and equipment protection are achieved. The rationality of its design directly affects the feeding accuracy, energy consumption, and operational stability. The pneumatic system needs to take into account multiple functions such as sealing, blowing, and auxiliary power, and form a linkage with the mechanical structure to ensure that materials do not leak or block during transportation.

氣路系統(tǒng)的核心構(gòu)成包括氣源裝置、控制元件與氣路接口三部分

The core components of the pneumatic system include the gas source device, control components, and pneumatic interface. The gas source usually comes from a compressed air station, which is dried and filtered before being transported to the feeder through the main pipeline. The pressure is generally controlled within a stable range to meet the requirements of different working conditions. The control components include solenoid valves, pressure regulating valves, pressure gauges, etc. The solenoid valves are responsible for controlling the on/off of the air circuit and can be linked with the rotation of the feeder impeller (such as triggering air supply once every rotation of the impeller); Pressure regulating valves are used to precisely control the pressure of each branch of the gas path. For example, the sealing gas pressure needs to be slightly higher than the pressure of the conveying pipeline to prevent material backflow. The air interface is distributed at key positions of the feeder housing: the sealing air interface is mostly located at the shaft seal at both ends of the impeller, forming an air curtain to block the material from entering the bearing; The blowing air interface is facing the clearance between the impeller and the dead corner of the shell, used to remove residual materials; The air supply interface is connected to the discharge port, and auxiliary materials enter the conveying pipeline.

氣路的密封功能是防止物料泄漏與環(huán)境污染的關(guān)鍵。軸封處的氣路通過持續(xù)通入低壓氣體

The sealing function of the gas path is the key to preventing material leakage and environmental pollution. The air path at the shaft seal is continuously filled with low-pressure gas, forming an annular air curtain between the impeller shaft and the housing. This not only prevents powder materials from penetrating into the bearing chamber and causing wear, but also prevents untreated external air from entering the conveying system and disrupting pressure balance. The sealing pressure should be adjusted according to the characteristics of the conveyed material: for ultrafine powders, the pressure should be slightly higher than the pressure inside the shell to prevent dust penetration; For coarse particulate materials, the pressure can be appropriately reduced to reduce energy consumption. When the sealing gas pressure drops abnormally (such as pipeline blockage or gas source interruption), the system will trigger an alarm, prompting the operator to check the gas path to prevent material leakage from causing equipment failure.

吹掃氣路的作用是清理設(shè)備內(nèi)部殘留物料

The function of blowing the air path is to clean the residual materials inside the equipment and avoid clumping and blockage. During the rotation clearance of the impeller, the blowing air passes through the directional nozzle to blow away the material residue between the blades, especially for materials with strong moisture absorption or high viscosity, which can prevent them from adhering to the inner wall of the shell and forming material deposits. The timing of opening the blowing gas is linked to the operation status of the feeder: during normal conveying time, intermittent blowing is carried out (such as every 10 minutes), and before stopping, a comprehensive blowing is carried out to ensure that there is no material residue inside. The pressure of the blowing gas should be moderate. If it is too high, it may cause the material to recoil into the silo, while if it is too low, it cannot effectively remove the residue. In practical applications, it needs to be repeatedly adjusted based on the fluidity of the material.

補(bǔ)氣氣路能輔助改善物料輸送條件

The air supply circuit can assist in improving material conveying conditions and enhancing system stability. When there is pressure fluctuation in the conveying pipeline, the supplementary gas path can supplement an appropriate amount of gas to the discharge port, balance the pressure difference between the pipeline and the feeder outlet, and avoid material accumulation caused by sudden pressure drops. For materials with high specific gravity or poor fluidity, supplementing air can enhance the carrying capacity of the airflow and prevent the formation of bridging blockages at the outlet. The amount of air supply should match the amount of material conveyed, which can be monitored and adjusted through a flow meter. Usually, the amount of air supply is a certain proportion of the conveying air volume, which can meet the needs of auxiliary conveying without excessively diluting the material concentration.

氣路系統(tǒng)常見問題多與壓力失衡、雜質(zhì)堵塞相關(guān)

Common problems in pneumatic systems are often related to pressure imbalance and impurity blockage. Unstable pressure can lead to seal failure or incomplete blowing, often caused by fluctuations in gas source pressure, malfunctioning regulating valves, or pipeline leaks. It is necessary to regularly check the gas source pressure curve, calibrate the accuracy of the regulating valve, and conduct air tightness tests on pipeline interfaces (such as applying soapy water to observe for bubbles). Air path blockage is often caused by incomplete filtration of moisture and oil in compressed air, which condenses into ice or adheres to the valve diameter in low temperature environments. It can be solved by installing high-efficiency filters (such as precision filter cartridges), regularly draining water and oil, and maintaining temperature in the air path pipeline in cold areas to prevent freezing and blockage.

本文由旋轉(zhuǎn)供料器友情奉獻(xiàn).更多有關(guān)的知識請點(diǎn)擊:http://www.513951.com/我們將會對您提出的疑問進(jìn)行詳細(xì)的解答,歡迎您登錄網(wǎng)站留言.

This article is dedicated to friendship For more information, please click: We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

相關(guān)文章 / Recommended news

相關(guān)產(chǎn)品 / Related products

2024 濟(jì)南鑫魯泉盛機(jī)械設(shè)備有限公司 備案號:魯ICP備18012408號-3 魯公網(wǎng)安備37018102000806號

氣力輸送

氣力輸送  旋轉(zhuǎn)供料器

旋轉(zhuǎn)供料器  真空上料機(jī)

真空上料機(jī)  倉泵

倉泵  空氣懸浮磁懸浮鼓風(fēng)機(jī)

空氣懸浮磁懸浮鼓風(fēng)機(jī)  羅茨風(fēng)機(jī)

羅茨風(fēng)機(jī)  除塵器

除塵器  吸灰機(jī)/負(fù)壓除塵系統(tǒng)

吸灰機(jī)/負(fù)壓除塵系統(tǒng)  旋風(fēng)除塵器

旋風(fēng)除塵器  AV泵

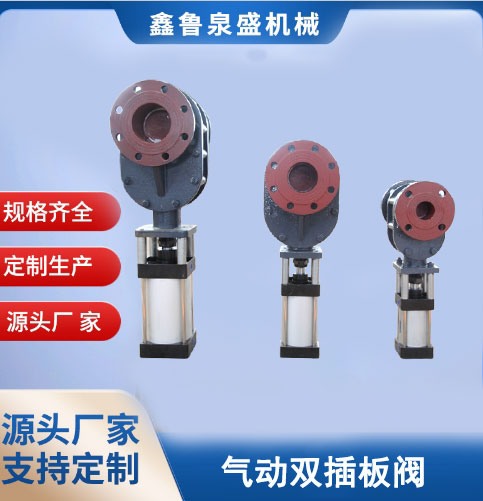

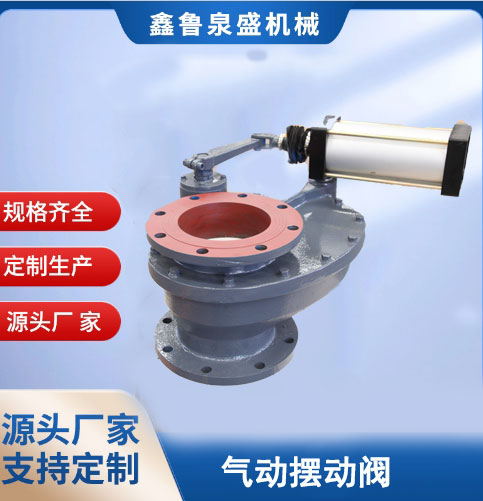

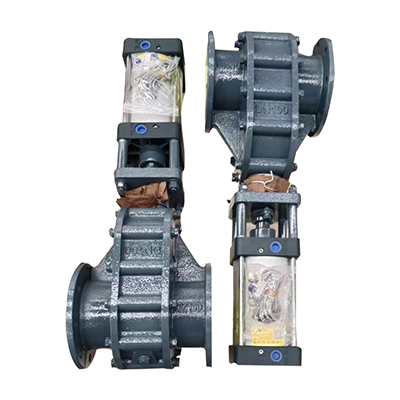

AV泵  分路閥/氣動閥門

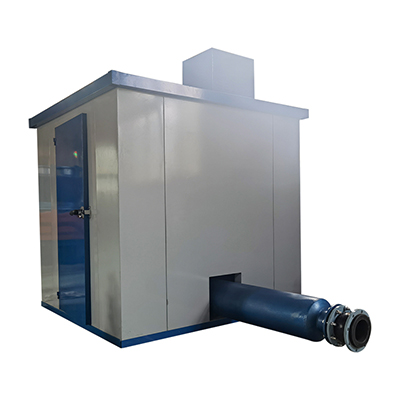

分路閥/氣動閥門  消音房

消音房  鼓風(fēng)機(jī)

鼓風(fēng)機(jī)