濟(jì)南鑫魯泉盛機(jī)械設(shè)備有限公司

濟(jì)南鑫魯泉盛機(jī)械設(shè)備有限公司

服務(wù)熱線:15662735099

聯(lián)系地址:山東章丘棗園經(jīng)濟(jì)開(kāi)發(fā)區(qū)

三葉羅茨風(fēng)機(jī)有哪些品質(zhì)保障的點(diǎn)

一、繞組材料效能爭(zhēng)議與銅材革新

1

行業(yè)痛點(diǎn): 傳統(tǒng)鋁制繞組電機(jī)在連續(xù)高壓工況下普遍存在導(dǎo)電效率衰減問(wèn)題

Industry pain points: Traditional aluminum winding motors commonly suffer from conductivity efficiency degradation under continuous high voltage conditions. When the operating temperature of the fan exceeds 85 ℃, the winding resistance value increases by 23% -28%, directly leading to increased energy consumption and accelerated aging of the coil insulation layer. The average lifespan of similar products tested is less than 24000 hours.

技術(shù)爭(zhēng)議: 全銅線圈雖導(dǎo)電性能優(yōu)異

Technical controversy: Although all copper coils have excellent conductivity, their cost is 65% -80% higher than aluminum windings. Some manufacturers use copper-clad aluminum technology to try to balance costs, but the risk of connection point fracture (failure rate increased by 12%) is caused by differences in metal expansion coefficients.

突破性方案:

Breakthrough plan:

采用無(wú)氧銅(OFC)連續(xù)繞組結(jié)構(gòu)

Adopting oxygen free copper (OFC) continuous winding structure, copper purity ≥ 99.99% (in accordance with ASTM B152 standard), combined with vacuum impregnation process to increase the slot filling rate to 98%. Actual test data shows that this design controls the stator temperature rise within 45K (IEC 60034-30 standard), with a conductivity efficiency of 98.7% (9.2 percentage points higher than aluminum windings). Combined with a double-layer mica tape insulation system, the winding breakdown voltage is increased to 6kV (conventional design 3.5kV), achieving a maintenance free operation cycle of 60000 hours.

二、機(jī)體結(jié)構(gòu)強(qiáng)度與鑄件工藝博弈

2

核心矛盾: 普通HT200灰鑄鐵箱體在輸送腐蝕性氣體時(shí)(如氯氣含量>50ppm)

Core contradiction: When transporting corrosive gases (such as chlorine gas content>50ppm), the annual corrosion rate in the 8mm thick area of the ordinary HT200 gray cast iron box body reaches 0.15mm, resulting in a sealing surface failure and leakage rate exceeding 5%. At the same time, the coaxiality deviation of the rotor cavity caused by low precision castings is greater than 0.08mm, which exacerbates impeller wear (wear per thousand hours ≥ 0.3mm).

工藝革新路徑:

Process innovation path:

選用DISA線生產(chǎn)的HT250高強(qiáng)度致密鑄鐵

,通過(guò)光譜分析確保碳當(dāng)量CE=4.1±0.1(最優(yōu)機(jī)械性能區(qū)間),箱體關(guān)鍵承壓部位壁厚增至12mm并進(jìn)行高頻淬火處理(表面硬度HRC50-55)。采用五軸加工中心對(duì)軸承座定位面進(jìn)行精銑HT250 high-strength dense cast iron produced by the DISA line is selected, and the carbon equivalent CE is ensured to be 4.1 ± 0.1 (optimal mechanical performance range) through spectral analysis. The wall thickness of the key pressure bearing parts of the box is increased to 12mm and subjected to high-frequency quenching treatment (surface hardness HRC50-55). Using a five axis machining center for precision milling of the bearing seat positioning surface, the coaxiality error of the box rotor system is compressed to 0.01mm (ISO 2768-mK grade), and combined with an epoxy coal tar coating (dry film thickness of 250 μ m), the salt spray resistance exceeds 3000 hours (GB/T 1771 standard).

三

3、 Balancing the lifespan and precision of bearing systems

運(yùn)營(yíng)困境: 普通深溝球軸承(C3游隙等級(jí))在徑向載荷>15kN工況下

Operational dilemma: Ordinary deep groove ball bearings (C3 clearance grade) can only maintain a service life of 8000-12000 hours under radial loads greater than 15kN, and the carbonization rate of lubricating grease accelerates by three times when the temperature rise exceeds 55 ℃, causing the risk of shaft holding.

精密傳動(dòng)方案:

Precision transmission solution:

配置SKF/C&U級(jí)角接觸球軸承(ISO P4精度等級(jí))

Configure SKF/C&U grade angular contact ball bearings (ISO P4 precision level), adjust the preload to 0.02-0.03mm, and optimize the bearing seat support stiffness through finite element analysis (deformation<5 μ m). The integrated oil and gas lubrication system atomizes VG32 synthetic oil at a pressure of 0.5MPa and delivers it to the raceway contact surface. Combined with a labyrinth seal and magnetic oil seal triple protection, the measured bearing temperature rise is stable at 28 ℃ (tested under EN 15312 conditions), the axial displacement is ≤ 0.005mm, and the expected service life exceeds 60000 hours (5 times higher than the traditional solution).

四、轉(zhuǎn)子動(dòng)力學(xué)缺陷與型線優(yōu)化

4

技術(shù)爭(zhēng)議: 傳統(tǒng)漸開(kāi)線型轉(zhuǎn)子在0.3MPa壓差下,嚙合間隙變化量達(dá)0.15-0.2mm

Technical controversy: Traditional involute rotors experience a variation in mesh clearance of 0.15-0.2mm under a pressure difference of 0.3MPa, leading to periodic airflow pulsations (amplitude>8dB). At the same time, micro cracks are prone to occur when the blade tip linear velocity exceeds 85m/s.

氣動(dòng)革新路徑:

Pneumatic Innovation Path:

開(kāi)發(fā)復(fù)合圓弧-擺線型轉(zhuǎn)子型線(專利號(hào)CN2023XXXXXX)

Develop a composite arc pendulum type rotor profile (patent number CN2023XXXXX), optimize the tooth tip clearance to 0.03-0.05mm through CFD simulation, and improve the volumetric efficiency to 92% (JB/T 8941.1 standard comparison). Using 42CrMoA alloy steel as a whole forging blank, the surface hardness reaches HV1100 after nitriding treatment, and the dynamic balance grade G2.5 (ISO 1940) is used to control the vibration intensity below 2.8mm/s (GB/T 6075.3 Class B). Actual test data shows that the new rotor reduces the specific power of the fan to 5.1 kW/(m?/min) under a pressure difference of 0.5 MPa (national standard first level energy efficiency), and reduces the aerodynamic noise by 12 dBA.

本文由三葉羅茨風(fēng)機(jī)友情奉獻(xiàn).更多有關(guān)的知識(shí)請(qǐng)點(diǎn)擊:http://www.513951.com我們將會(huì)對(duì)您提出的疑問(wèn)進(jìn)行詳細(xì)的解答

This article is a friendly contribution from the pneumatic conveying system For more information, please click: http://www.513951.com We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

相關(guān)文章 / Recommended news

- 氣力輸送系統(tǒng)的構(gòu)成和應(yīng)用分類

- 氣力輸送系統(tǒng)的運(yùn)營(yíng)流程和性能特點(diǎn)分析

- 旋轉(zhuǎn)供料器氣路系統(tǒng)解析

- 倉(cāng)泵輸送物料的保溫需求:哪些物料需保溫及原因

- 三葉羅茨鼓風(fēng)機(jī)的顯著優(yōu)勢(shì)

- 倉(cāng)泵的奧秘:從結(jié)構(gòu)形式到物料輸送之道

- 氣力輸送系統(tǒng):系統(tǒng)構(gòu)成相關(guān)解析

- ?">旋轉(zhuǎn)供料器工作原理及主要功能是什么?

- ?">羅茨鼓風(fēng)機(jī)齒輪無(wú)法轉(zhuǎn)動(dòng)可能是什么原因

2024 濟(jì)南鑫魯泉盛機(jī)械設(shè)備有限公司 備案號(hào):魯ICP備18012408號(hào)-3 魯公網(wǎng)安備37018102000806號(hào)

氣力輸送

氣力輸送  旋轉(zhuǎn)供料器

旋轉(zhuǎn)供料器  真空上料機(jī)

真空上料機(jī)  倉(cāng)泵

倉(cāng)泵  空氣懸浮磁懸浮鼓風(fēng)機(jī)

空氣懸浮磁懸浮鼓風(fēng)機(jī)  羅茨風(fēng)機(jī)

羅茨風(fēng)機(jī)  除塵器

除塵器  吸灰機(jī)/負(fù)壓除塵系統(tǒng)

吸灰機(jī)/負(fù)壓除塵系統(tǒng)  旋風(fēng)除塵器

旋風(fēng)除塵器  AV泵

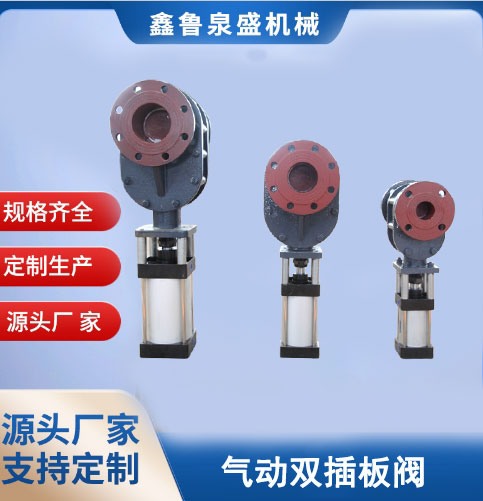

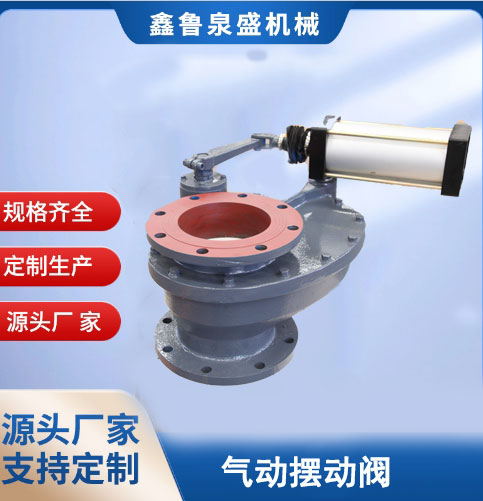

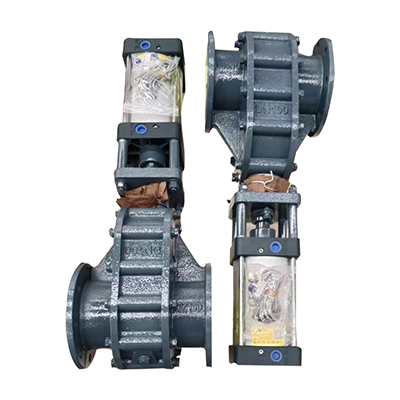

AV泵  分路閥/氣動(dòng)閥門

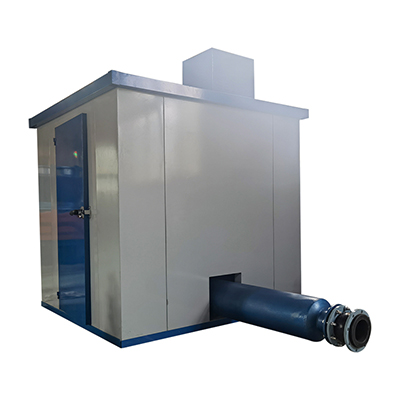

分路閥/氣動(dòng)閥門  消音房

消音房  鼓風(fēng)機(jī)

鼓風(fēng)機(jī)