- 氣力輸送系統(tǒng)的構(gòu)成和應(yīng)用分類(lèi)

- 氣力輸送系統(tǒng)的運(yùn)營(yíng)流程和性能特點(diǎn)分析

- 旋轉(zhuǎn)供料器氣路系統(tǒng)解析

- 倉(cāng)泵輸送物料的保溫需求:哪些物料需保溫及原因

- 三葉羅茨鼓風(fēng)機(jī)的顯著優(yōu)勢(shì)

- 倉(cāng)泵的奧秘:從結(jié)構(gòu)形式到物料輸送之道

- 氣力輸送系統(tǒng):系統(tǒng)構(gòu)成相關(guān)解析

- 旋轉(zhuǎn)供料器工作原理及主要功能是什么?聯(lián)系我們

濟(jì)南鑫魯泉盛機(jī)械設(shè)備有限公司

濟(jì)南鑫魯泉盛機(jī)械設(shè)備有限公司

服務(wù)熱線:15662735099

聯(lián)系地址:山東章丘棗園經(jīng)濟(jì)開(kāi)發(fā)區(qū)

水泥罐倉(cāng)除塵器怎么安裝?

一、安裝前準(zhǔn)備工作

1

設(shè)備選型核查

Equipment selection verification

在安裝前必須嚴(yán)格核對(duì)除塵器型號(hào)規(guī)格與水泥罐倉(cāng)的匹配性

Before installation, it is necessary to strictly check the compatibility between the dust collector model and specifications and the cement tank compartment, including key parameters such as processing air volume and filtration area, to ensure that the equipment performance meets the requirements of the working conditions. At the same time, it is necessary to check whether the appearance of the equipment is intact and whether there is any transportation damage to the core components such as the internal filter bag.

工具材料準(zhǔn)備

Preparation of tools and materials

安裝需配備完整的工具套裝:包括不同規(guī)格的扳手套裝(8-19mm)

Installation requires a complete set of tools, including wrench sets of different specifications (8-19mm), electric screwdrivers, level gauges, sealant guns, and other professional tools. In terms of materials, it is necessary to prepare high-temperature resistant sealant, 304 stainless steel bolt sets (including flat pads and spring washers), explosion-proof electrical wiring terminals, etc.

現(xiàn)場(chǎng)環(huán)境準(zhǔn)備

On site environment preparation

安裝區(qū)域需進(jìn)行徹底清理

The installation area needs to be thoroughly cleaned, using an industrial vacuum cleaner to remove dust from the top of the tank compartment. Set up isolation and warning areas to avoid cross operation affecting installation quality. Prepare temporary shelter facilities for rain and dust prevention to ensure that the installation process is not affected by weather.

二

2、 Standardized installation process

定位測(cè)量

Positioning measurement

采用全站儀進(jìn)行精確定位

Using a total station for precise positioning, determine the installation coordinates of the dust collector based on the CAD drawings of the tank structure. Consider the maintenance space requirements (it is recommended to retain a circular channel of ≥ 800mm) and avoid key components such as the safety valve on the top of the warehouse.

支架安裝

Bracket installation

選用δ=8mm碳鋼支架

,采用M16化學(xué)錨栓固定。安裝時(shí)使用激光水平儀校準(zhǔn)Choose a carbon steel bracket with δ=8mm and fix it with M16 chemical anchor bolts. During installation, a laser level should be used for calibration, and the horizontal deviation should be controlled within 3 ‰. The welding area needs to undergo rust prevention treatment and complete a 24-hour load-bearing test.

管道連接

Pipeline connection

(1)進(jìn)氣管道采用法蘭連接,石棉墊片需做浸油處理

(1) The intake pipeline adopts flange connection, and the asbestos gasket needs to be treated with oil immersion

(2)出風(fēng)管道安裝膨脹節(jié)補(bǔ)償熱位移

(2) Installation of expansion joints to compensate for thermal displacement in the air outlet duct

(3)所有接口需進(jìn)行氣密性檢測(cè)(0.05MPa保壓測(cè)試)

(3) All interfaces need to undergo air tightness testing (0.05MPa pressure holding test)

主體安裝

Main installation

吊裝時(shí)使用專(zhuān)用平衡梁

Use a dedicated balance beam during lifting, and tighten the bolts with a torque wrench after positioning (torque values refer to GB/T3098.1). The final verticality deviation is ≤ 2mm/m.

電氣安裝

Electrical installation

(1)按IEC標(biāo)準(zhǔn)敷設(shè)阻燃電纜

(1) Lay flame-retardant cables according to IEC standards

(2)防爆區(qū)域需使用ExdⅡBT4等級(jí)電器元件

(2) Explosion proof areas require the use of Exd Ⅱ BT4 grade electrical components

(3)接地電阻測(cè)試值≤4Ω

(3) Grounding resistance test value ≤ 4 Ω

本文由倉(cāng)頂除塵器友情奉獻(xiàn).更多有關(guān)的知識(shí)請(qǐng)點(diǎn)擊:http://www.513951.com我們將會(huì)對(duì)您提出的疑問(wèn)進(jìn)行詳細(xì)的解答

This article is a friendly contribution from the pneumatic conveying system For more information, please click: http://www.513951.com We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

相關(guān)文章 / Recommended news

- 氣力輸送系統(tǒng)的構(gòu)成和應(yīng)用分類(lèi)

- 氣力輸送系統(tǒng)的運(yùn)營(yíng)流程和性能特點(diǎn)分析

- 旋轉(zhuǎn)供料器氣路系統(tǒng)解析

- 倉(cāng)泵輸送物料的保溫需求:哪些物料需保溫及原因

- 三葉羅茨鼓風(fēng)機(jī)的顯著優(yōu)勢(shì)

- 倉(cāng)泵的奧秘:從結(jié)構(gòu)形式到物料輸送之道

- 氣力輸送系統(tǒng):系統(tǒng)構(gòu)成相關(guān)解析

- ?">旋轉(zhuǎn)供料器工作原理及主要功能是什么?

- ?">羅茨鼓風(fēng)機(jī)齒輪無(wú)法轉(zhuǎn)動(dòng)可能是什么原因

2024 濟(jì)南鑫魯泉盛機(jī)械設(shè)備有限公司 備案號(hào):魯ICP備18012408號(hào)-3 魯公網(wǎng)安備37018102000806號(hào)

氣力輸送

氣力輸送  旋轉(zhuǎn)供料器

旋轉(zhuǎn)供料器  真空上料機(jī)

真空上料機(jī)  倉(cāng)泵

倉(cāng)泵  空氣懸浮磁懸浮鼓風(fēng)機(jī)

空氣懸浮磁懸浮鼓風(fēng)機(jī)  羅茨風(fēng)機(jī)

羅茨風(fēng)機(jī)  除塵器

除塵器  吸灰機(jī)/負(fù)壓除塵系統(tǒng)

吸灰機(jī)/負(fù)壓除塵系統(tǒng)  旋風(fēng)除塵器

旋風(fēng)除塵器  AV泵

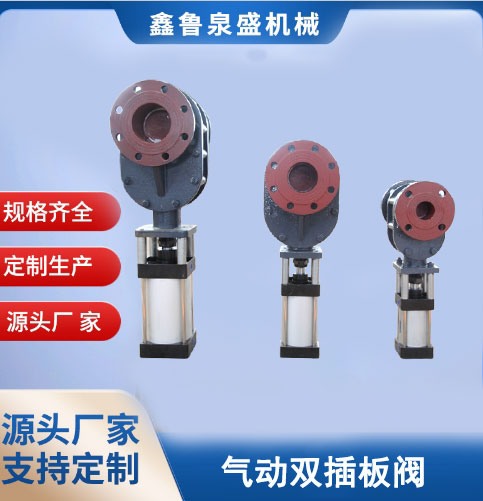

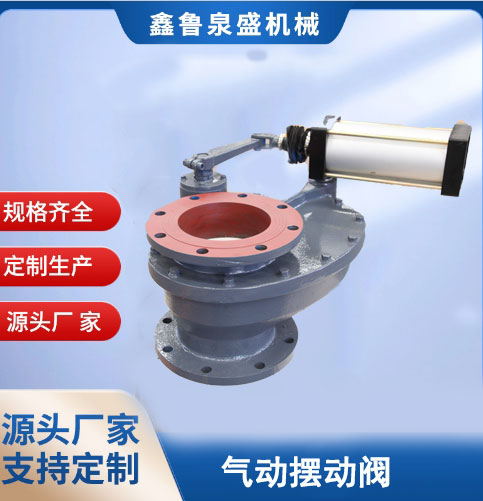

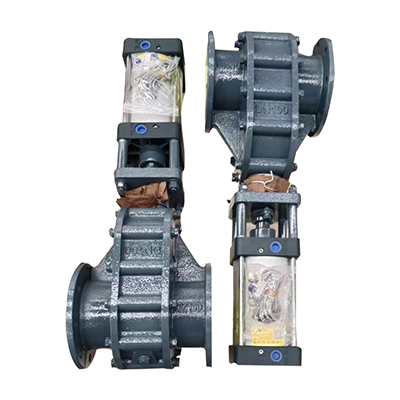

AV泵  分路閥/氣動(dòng)閥門(mén)

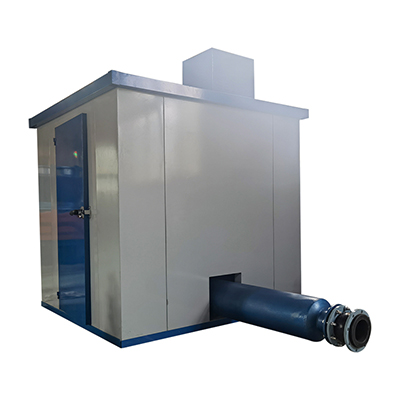

分路閥/氣動(dòng)閥門(mén)  消音房

消音房  鼓風(fēng)機(jī)

鼓風(fēng)機(jī)